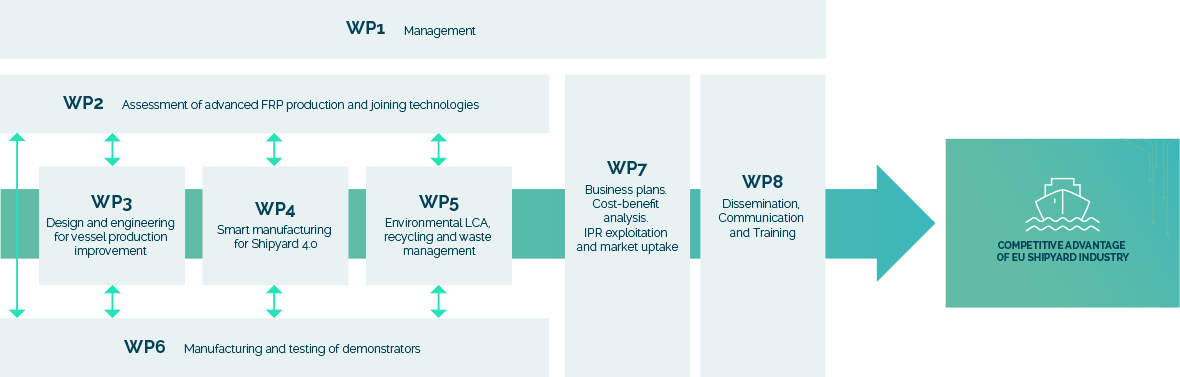

Structure

FIBRE4YARDS will last for 36 months, from January 2021 to December 2023.

The technical implementation of the project will be performed via five major Work Packages (WP):

WP2

Assessment of advanced FRP production and joining technologies

FIBRE4YARDS will:

- Develop new FRP production technologies and analyse their best implementation in shipyards

- Investigate how advanced production processes already used in other industries can be adapted to the marine sector

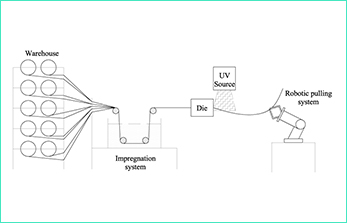

The targeted technologies are:

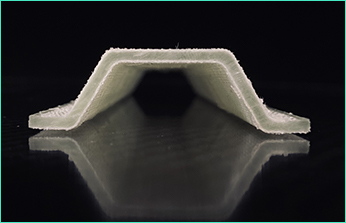

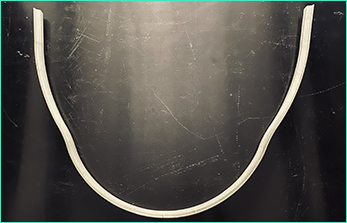

Transversal section ©INDUSTRIAS QUIMICAS IRURENA

Vessel profile ©INDUSTRIAS QUIMICAS IRURENA

Free shape diagram ©INDUSTRIAS QUIMICAS IRURENA

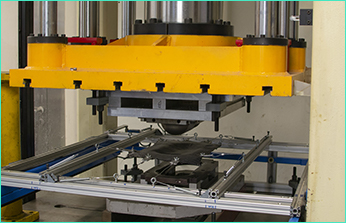

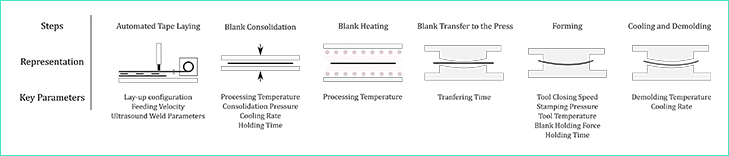

Hot stamping ©INEGI

Hot stamped and over-injected part ©INEGI

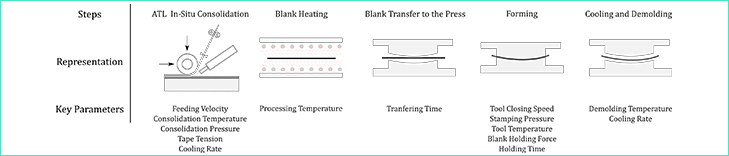

Automated tape laying ©INEGI

Automated Tape Laying In situ Hot stamping ©INEGI

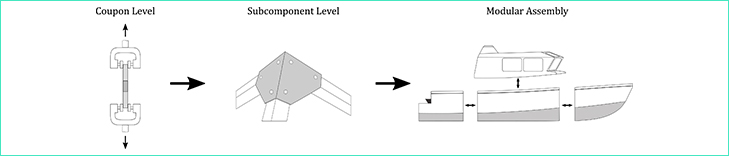

Modular assembly ©INEGI

Robotic 3D printing ©10XL

Robotic CNC routing ©10XL

Robotic automatic tape placement ©10XL

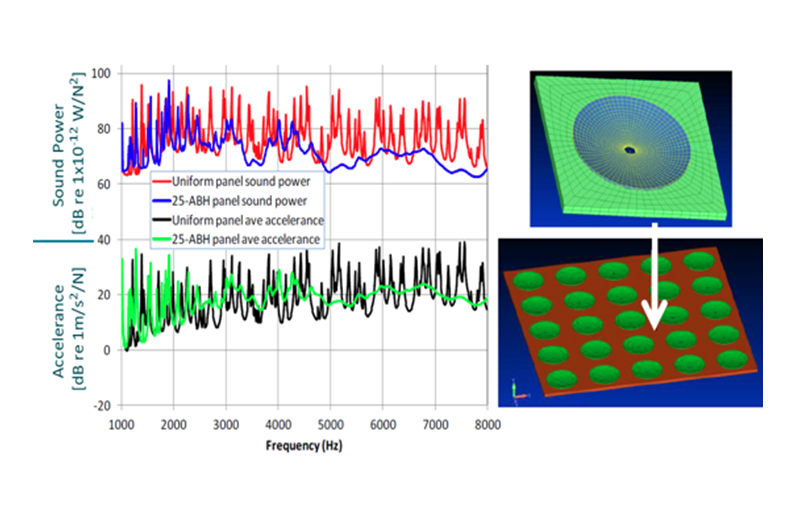

Reference: Stephen C. CONLON et al, Enhancing the low frequency vibration reduction performance of plates with embedded Acoustic Black Holes, INTERNOISE 2014, Melbourne-AUS, 16-19 Nov14 ©IRT

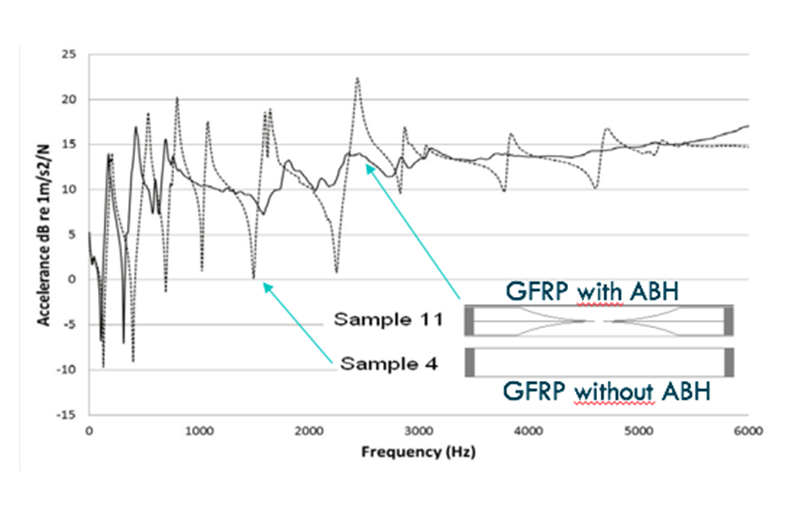

Reference: BOWYER, E.P. and KRYLOV, V.V., 2015. A review of experimental investigations into the acoustic black hole effect and its applications for reduction of flexural vibrations and structure-borne sound; InterNoise 2015 (https://dspace.lboro.ac.uk/2134/18927) ©IRT

Curve Works adaptive mould “Bee” is 2.5 x 1.3 m, used for higher curvature parts. ©CURVE WORKS

Curve Works adaptive mould “Ant” is 3.8 x 1.8 m, used for large parts. ©CURVE WORKS

WP3

Design and engineering for vessel production improvement

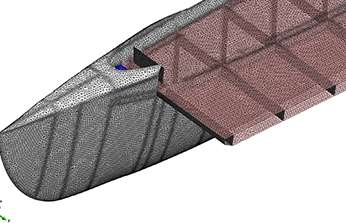

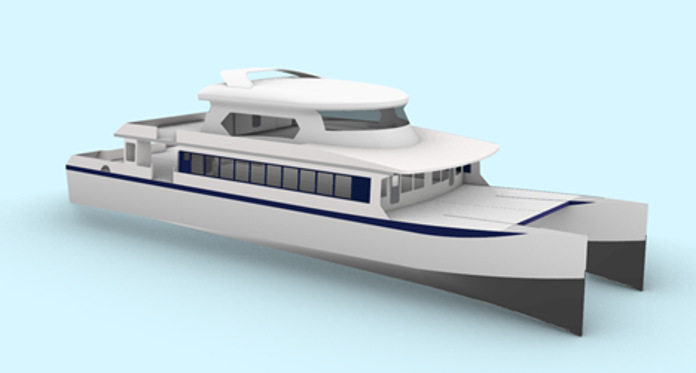

FIBRE4YARDS will re-design two ships, optimized by means of the developed production methods, and enabled to be produced in a Shipyard 4.0 environment. The numerical models and formulations to be developed for predicting the performance of composite structures manufactured with the advanced technologies introduced and investigated in the project, will be implemented in the commercial FEA (Finite Element Analysis) code Tdyn-RamSeries in order to make them industry-ready.

CFD simulation of patrol boat in waves, performed with CompassIS’s software Tdyn-CDF+HT ©COMPASS Ingeniería y Sistemas S.A.

Hydro-elastic coupling simulation performed by CIMNE, with CompassIS’s codes Tdyn-RamSeries and Tsyn-SeaFEM ©COMPASS Ingeniería y Sistemas S.A.

Patrol boat ©COMPASS Ingeniería y Sistemas S.A.

Catamaran ©COMPASS Ingeniería y Sistemas S.A.

Patrol Boat images courtesy of Nautatec SL ©COMPASS Ingeniería y Sistemas S.A.

« Catamaran », © TSI.

WP4

Smart manufacturing for Shipyard 4.0

In order to define a new generation of 4.0 shipyards, FIBRE4YARDS will:

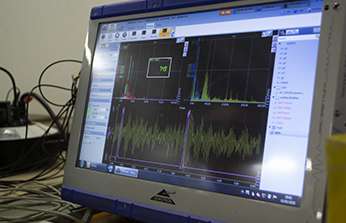

- Develop monitoring strategies to obtain required data for continuous quality control and production assets maintenance

- Develop a real-time Digital Twin Model of the shipyard fed by an IoT enabled monitoring system, allowing to control the different production and maintenance processes during the vessel construction

- Adaptation of the monitoring system for its validation in the production technologies and demonstrators of the FIBRE4YARDS project

- Define applications of smart technology to shipbuilding based on IoT to develop the Shipyard 4.0 concept and improve production and maintenance processes

- Define cyber-security measures in the Shipyard 4.0 strategy for avoiding data-loss or data-stealing risks

Real-time asset monitoring ©TSI SL

Web platform analytics and data visualization tools ©TSI SL

Web platform ©TSI SL

Smart manufacturing ©Pixabay

Shipyard 4.0 ©TSI SL

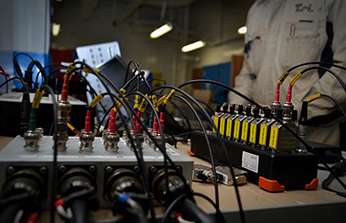

Sensor selection and installation ©TSI SL

Monitoring cabinet ©TSI SL

Digital twin ©TSI SL

Cybersecurity ©Pixabay

WP5

Environmental LCA, recycling and waste management

FIBRE4YARDS will conduct a Life Cycle Assessment (LCA) analysis of different advanced FRP production and joining technologies to assess their environmental impacts over the entire life cycle of ships

LCA analysis will be performed according to ISO 14040/14044 standards and based on environmental models such as ReCiPe 2016, IPCC 2013, etc.

Results of the LCA analysis will indicate which technology has the lowest environmental impact over the entire life cycle

WP6

Manufacturing and testing of demonstrators

All developments made in FIBRE4YARDS will be evaluated with the construction of two demonstrators:

- First demonstrator will contain elements produced with each of the production technologies developed.

It will be designed with the numerical tools developed in the project.

The construction of the demonstrator will also help to evaluate the performance of the Shipyard 4.0 technologies developed in FIBRE4YARDS. - Second demonstrator will be a 3D printed axe-bow.

This demonstrator will be also used to evaluate the performance of the IoT and the Shipyard 4.0 elements implemented during the project.

Demonstrator - topside ©NAVAL GROUP

Demonstrator - deck ©NAVAL GROUP

Demonstrator - deck ©NAVAL GROUP

Superstructure Frigate La Fayette (1980 – 1990)

Superstructure Frigate La Fayette (1980 – 1990)

WP7

Business plans. Cost-benefit analysis. IPR exploitation and market uptake

©Shutterstock

WP7 will provide economic assessment support for project partners in order to make rapid technical development decisions throughout the progress of the project. To perform a market research, business trends monitoring and as the conclusions of the cost-benefits analysis, a global business plan will be elaborated. This WP will also pay special attention to protecting the generated results with the provision of a sound exploitation strategy and IP management.

WP8

Dissemination, Communication and Training

©Shutterstock

WP8 will ensure proper dissemination of the project results, to promote European Commission`s commitment with R&D projects and to benefit the research and industrial community. In order to promote timely awareness of the project’s activities, various dissemination channels will be implemented: effectively exchanging with the research community, both in academia and industry, but also communicating to the European general public by means of social media profiles and the project website.